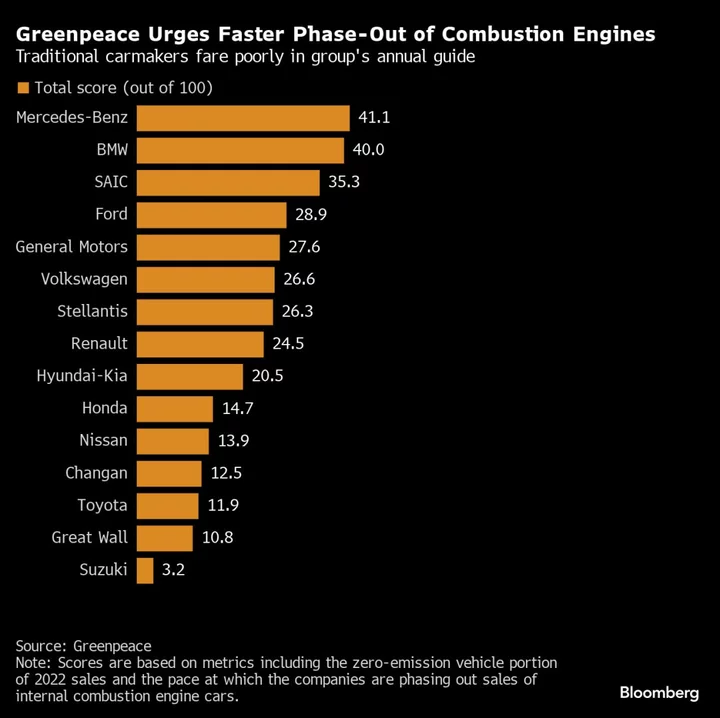

Suzuki Motor Co. ranked last while other Japanese carmakers fared poorly in Greenpeace’s latest assessment of their progress in phasing out fossil fuels and shifting to electric cars.

Toyota Motor Corp., Honda Motor Co. and Nissan Motor Co. ranked in the bottom half among the 15 traditional vehicle manufacturers the environment-activist group evaluated in an annual report released Thursday. Mercedes-Benz Group AG, BMW AG and China’s SAIC Motor Corp. placed in the top three.

While Japan’s top carmakers pioneered the use of small batteries and electric motors to make internal combustion engines more efficient, they’ve been slower in embracing fully electric vehicles. The companies have formed a united front in arguing the merits of using multiple approaches to decarbonizing cars, putting them at odds with Greenpeace and other advocacy groups.

“Suzuki’s decarbonisation and electrification performance is almost nonexistent in a time when nearly all major carmakers are transitioning away from ICE vehicles,” Greenpeace said in the report.

Japanese brands are now losing market share in China, Europe and the US as a result of having dragged their feet on EVs, Greenpeace said. The annual ranking is based on metrics including sales of zero-emission vehicles powered entirely by batteries and hydrogen fuel cells. It doesn’t account for hybrid powertrains.

Representatives for Suzuki and Toyota said they couldn’t comment before the report is made public.

Passenger vehicles account for the largest source of emissions from the transportation sector, making up almost a fifth of global emissions, according to the International Energy Association. Global carmakers should end the sale of ICE vehicles in Europe by 2028, and in the US, China, South Korea and Japan by 2030, Greenpeace said, arguing that those phase-out dates are what’s necessary to slow global warming.

Toyota, the world’s biggest carmaker by volume, has accelerated efforts to sell more EVs, setting a target of selling 1.5 million annually by 2026, and 3.5 million by 2030. The company invited media to workshops in June and September in which they revealed the progress they’ve made in developing solid state batteries, large casting machines and other tools that will be used to scale EV production in the coming years.